How to Become a Welder

- What Welders Do

- Core Skills for Welding Success

- Typical Work Environments

- How to Become a Welder (5 Steps)

- State Welding Requirements

- Education and Certification Options

- Career Development and Growth

- Training Duration and Cost Overview

- Pros and Considerations

- Take the First Step Toward a Welding Career

- Quick Facts: Welding Training, Skills, and Industry Outlook

Ever wondered how bridges, ships, or high-rise buildings stay connected?

Welders make it happen.

Welding combines technical skill and precision craftsmanship to join and shape the metal structures that power our world.

If you enjoy building, hands-on work, and creating something tangible, welding can be a rewarding trade with lasting impact.

What Welders Do

Welders use heat and electricity to fuse metal parts together. Their work is essential in manufacturing, construction, and repair settings where precision and safety are critical.

Common Duties

- Read blueprints and technical drawings

- Set up and maintain welding tools and materials

- Operate MIG, TIG, Stick, or Flux-core welding systems

- Inspect welds for quality standards

- Work safely around high temperatures and equipment

Welding is both a craft and a science — it requires focus, control, and dedication to quality.

Core Skills for Welding Success

- Steady hand and strong attention to detail

- Mechanical aptitude and spatial awareness

- Ability to follow blueprints and procedures

- Physical stamina and safety awareness

- Comfort working in varied environments

Typical Work Environments

Welders work in diverse industries and locations, including:

- Construction and infrastructure projects

- Manufacturing and fabrication facilities

- Automotive and aerospace production

- Shipyards and marine repair

- Energy and utility systems

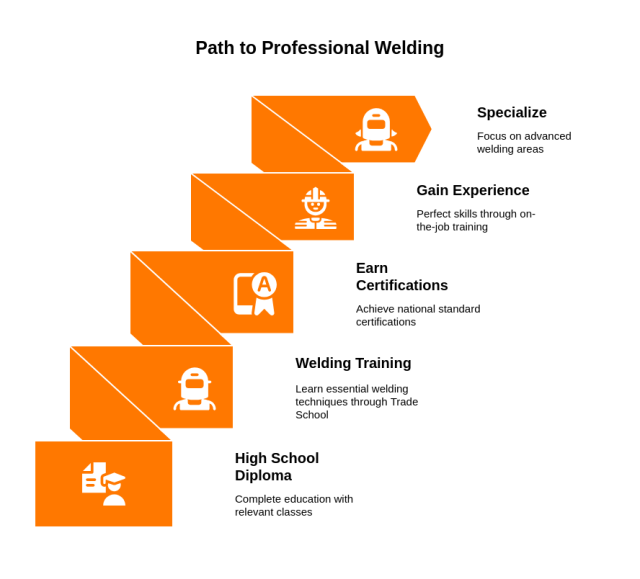

How to Become a Welder (5 Steps)

Becoming a welder generally takes 6 months to 2 years, depending on your training path and level of specialization.

1. Earn a High School Diploma or GED

Focus on math, shop, and mechanical drawing. These courses build the foundation for understanding measurements and materials.

2. Complete a Welding Training Program

Enroll in a technical college or trade school that offers instruction in:

- Basic Welding Processes: MIG, TIG, Stick, and Flux-core

- Blueprint Reading: Learning to interpret technical drawings

- Safety and Materials: Proper handling and inspection techniques

Programs may result in a certificate or diploma upon completion.

3. Build Practical Experience

Many welders begin as apprentices or assistants, gaining on-the-job experience under skilled professionals while continuing their training.

4. Earn Industry Certifications

Certifications help demonstrate your skill level to employers. Common options include:

- American Welding Society (AWS) D1.1 – Structural Steel

- NCCER Welding Certification – Nationally recognized standards

- ASME Section IX – Pressure vessel and pipe welding

Requirements vary depending on your work environment and employer expectations.

5. Continue Learning and Specialize

Experienced welders often expand into specialized areas such as pipe welding, inspection, or advanced fabrication. Some move into supervisory or training roles over time.

State Welding Requirements

Each state has its own approach to welding qualifications. Some rely on employer-based performance tests, while others reference national standards.

| State | Guide |

|---|---|

| Texas | Welding in Texas |

| Florida | Welding in Florida |

| California | Welding in California |

Explore Welding Requirements by State »

Education and Certification Options

| Pathway | Typical Duration | Outcome |

|---|---|---|

| Certificate or Diploma | 6–18 months | Entry-level readiness |

| Associate Degree | 2 years | Broader technical understanding |

| Apprenticeship | 3–4 years | Paid hands-on training |

| Advanced Certification | Varies | Specialized credentials |

Career Development and Growth

Welding offers long-term potential for growth as your technical skill increases. With experience, welders may qualify for:

- Quality Assurance or Inspection roles

- Fabrication Supervision or Training positions

- Specialized Welding in high-precision industries

The welding trade evolves constantly with technology — continuous learning helps you stay competitive.

Training Duration and Cost Overview

- Training Timeframe: typically 6 months to 2 years

- Program Type: certificate, diploma, or associate degree

- Additional Credentials: AWS or NCCER certifications

Costs and schedules vary by school and program type. Check each provider for details about available formats and requirements.

Pros and Considerations

Take the First Step Toward a Welding Career

If you’re motivated by craftsmanship and precision, welding offers a practical way to build a skilled trade career.

Start by exploring accredited programs that teach the fundamentals of metal fabrication and safety.

🔧 Find Welding Training Near You

Quick Facts: Welding Training, Skills, and Industry Outlook

Welder Salary by State

Meet the author: Brad Fishbein is a Florida Licensed Mold Assessor and council-certified Microbial Investigator. He’s the founder of TradeCareerPath.com and has completed over 5,000 mold inspections since 2009. Brad now helps homeowners and tradespeople make smart decisions about mold, licensing, and skilled career paths.

Notice an update we should make?

We strive for accuracy. Contact us here if you see incorrect or outdated info on this page.