How to Become a CNC Machinist

Ever wondered who builds the precision parts that make airplanes fly, cars move, and machines run smoothly?

That’s what CNC machinists do they take raw metal and turn it into the components that power nearly every industry.

If you like working with your hands, solving puzzles, and seeing real results from your work at the end of each day, becoming a CNC machinist could be your next big move.

Let’s walk through what it’s really like the training, the tools, the pay, and the path.

What Does a CNC Machinist Actually Do?

CNC stands for Computer Numerical Control but don’t worry, this isn’t all coding and math. It’s about using advanced machines to cut, drill, shape, and finish materials with unbelievable precision.

On a typical day, you might:

- Read blueprints and digital design files

- Set up and calibrate machines like mills, lathes, and grinders

- Load metal stock and monitor production

- Inspect parts using precision tools (like micrometers and gauges)

- Adjust machine settings for accuracy and safety

Think of CNC machinists as part engineer, part artist they turn code and metal into parts that keep the world moving.

As automation expands, skilled CNC operators are more valuable than ever. These machines might be smart but they still need humans who understand precision, safety, and process.

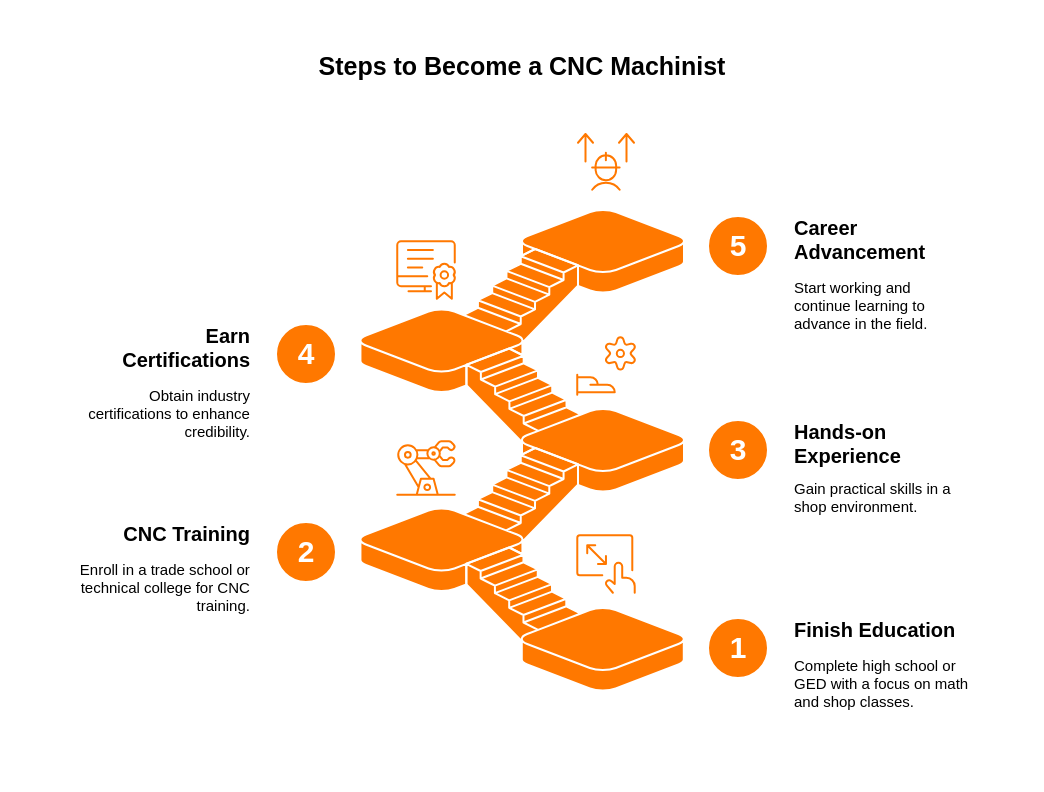

How to Become a CNC Machinist (5 Steps)

Here’s the play-by-play on how to get started:

-

Finish high school or get your GED

Focus on math, blueprint reading, and shop classes trust me, they’ll make your life easier later. -

Complete a CNC training program (6–18 months)

Trade schools and technical colleges teach you how to run, program, and maintain CNC equipment.

-

Get hands-on experience

The magic happens in the shop learning how to fine-tune machines, avoid mistakes, and understand materials. -

Earn industry certifications

These aren’t mandatory, but they’ll make you stand out. Common ones include:- NIMS (National Institute for Metalworking Skills)

- PMMI Mechatronics Certification

- CNC Setup/Programming Certificates from trade schools or manufacturers

-

Start working and keep learning

Machinists who keep upgrading their skills often move into CNC programming, quality control, or manufacturing management.

Certifications & Training Options

While you can start entry-level without certification, employers love candidates who’ve invested in their craft.

Common Paths:

- Trade School Programs – 6–18 months, focused and hands-on

- Apprenticeships – Earn while you learn in a shop environment

- Associate Degree in Precision Machining or Manufacturing Technology – 2 years, more advanced

Many machinists say the first time they saw a part they made go into a car, a plane, or a machine that’s when it clicked. “I made that.”

Skills That Make You Great at This

- Patience and precision (tiny mistakes = big problems)

- Comfort with computers and measurements

- Problem-solving under pressure

- Math and mechanical reasoning

- Focus and pride in craftsmanship

CNC machining is where technology meets touch and great machinists have both.

Career Growth & Opportunities

CNC machinists work in:

- Aerospace and automotive manufacturing

- Defense and industrial equipment

- Medical device fabrication

- Metal and plastics production

Future Career Paths:

- CNC Programmer

- Tool & Die Maker

- Manufacturing Supervisor

- Quality Control Inspector

Pros & Cons of CNC Machining

Pros:

- Hands-on, creative work

- High job security

- Great pay and benefits

- Real satisfaction in what you build

Cons:

- Long hours on your feet

- Repetitive tasks at times

- Noise and shop environment can be intense

Start Your CNC Career

CNC machinists are the quiet craftsmen behind almost everything we use from the phones in our pockets to the planes overhead.

If you’re ready to learn skills that are in demand everywhere (and actually make things that last), this trade might just be your calling.

Your future is waiting one perfectly cut piece at a time.

Cnc Machinist Salary by State

Meet the author: Brad Fishbein is a Florida Licensed Mold Assessor and council-certified Microbial Investigator. He’s the founder of TradeCareerPath.com and has completed over 5,000 mold inspections since 2009. Brad now helps homeowners and tradespeople make smart decisions about mold, licensing, and skilled career paths.

Notice an update we should make?

We strive for accuracy. Contact us here if you see incorrect or outdated info on this page.